Introduction

Calibration is a imperative area of ensuring the accuracy and reliability of measurements in a great number of fields, from manufacturing to laboratories. It's now not only a technical technique; it truly is the spine of satisfactory keep watch over and assurance. Without real calibration, how are we able to believe that our resources are delivering right readings? This handbook objectives to present a entire know-how of the calibration approach, breaking it down into digestible steps, so that you can expectantly navigate this necessary perform.

Understanding the Calibration Process: A Step-via-Step Guide

What is Calibration?

Calibration refers back to the task of fixing the precision and accuracy of measuring resources or units. By evaluating an device's outputs against commonly used requirements, we will discern any discrepancies and make necessary changes.

Why is Calibration Important?

Calibration ensures that instruments produce riskless outcomes. Inaccurate measurements can result in inaccurate products, defense disadvantages, and fiscal losses. Whether in prescribed drugs, engineering, or environmental tracking, having distinct details is non-negotiable.

Key Terms in Calibration

Before diving deeper into the calibration strategy, permit’s familiarize ourselves with a few key terms:

- Accuracy: How shut a measured cost is to the correct value. Precision: The repeatability of measurements lower than unchanged circumstances. Standard: A known reference element for assessment for the duration of calibration.

The Different Types of Calibration

Calibration can fluctuate substantially depending on the instrument or discipline. Here are some known versions:

Mass Calibration Temperature Calibration Pressure Calibration Electrical Calibration Dimensional CalibrationThe Steps Involved within the Calibration Process

Step 1: Identify Instruments Requiring Calibration

Begin by using creating an inventory of all gadgets used inside your operations that require common calibration.

Step 2: Establish a Calibration Schedule

Determine how aas a rule each one tool might be calibrated based totally on its utilization, organization thoughts, and market standards.

Step 3: Select Appropriate Standards

Using national or worldwide standards ensures that your calibration manner adheres to identified benchmarks.

Step 4: Perform Pre-calibration Checks

Always habits initial opinions to make certain gadgets are functioning thoroughly earlier origin formal calibration.

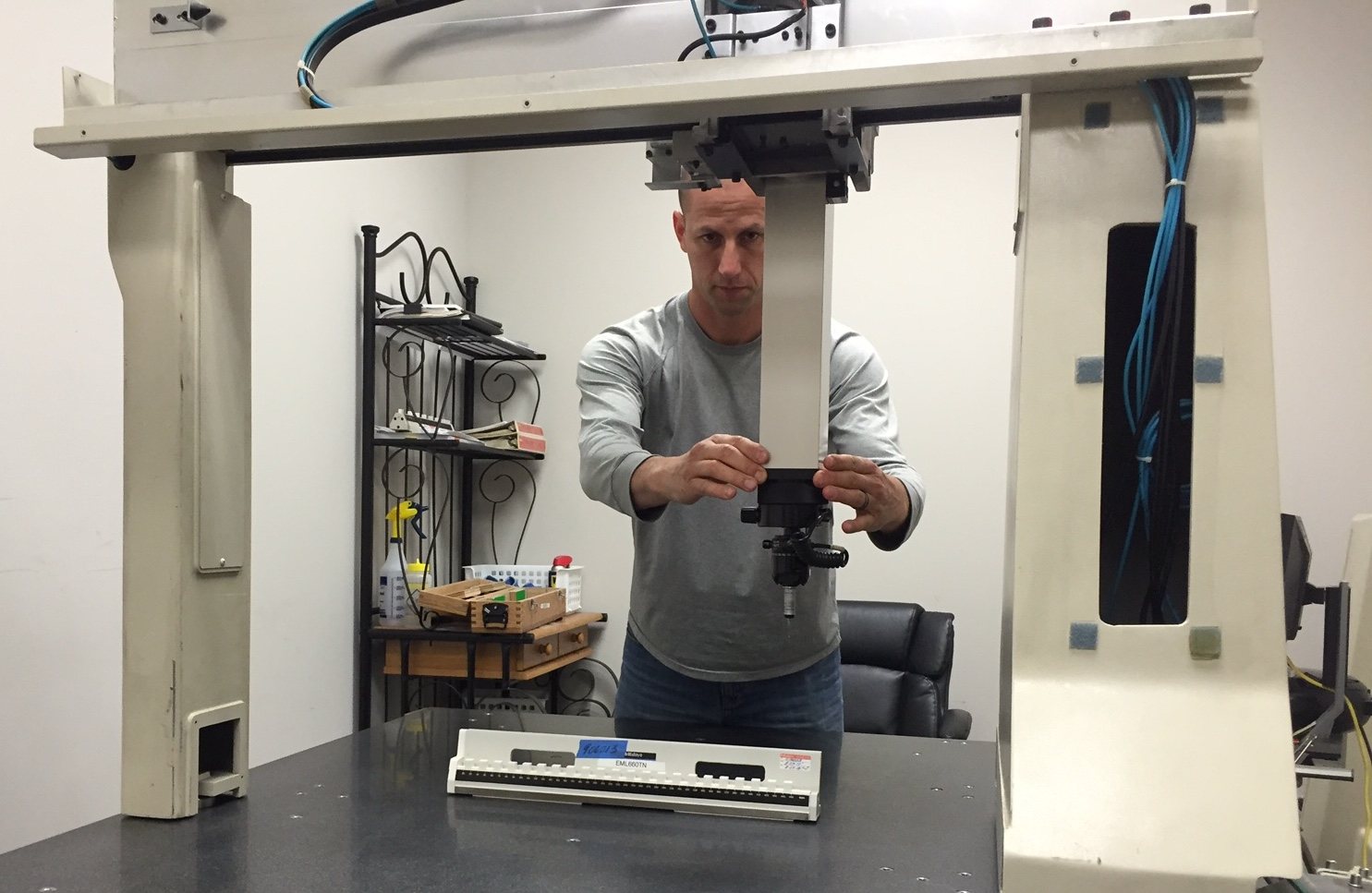

Step five: Calibrate Using Reference Standards

Compare your instrument's readings towards the ones from common reference requirements to recognize discrepancies.

Step 6: Document Results

Documentation must always comprise preliminary readings, ameliorations made, and remaining influence for future reference.

Step 7: Implement Adjustments if Necessary

If discrepancies are chanced on all through calibration, make valuable changes to carry the instrument to come back into compliance.

Tools Required for Effective Calibration

Having the suitable tools is very important for powerful calibration. Common methods encompass:

- Precision weights for mass calibration. Thermocouples for temperature checks. Pressure gauges for strain measurement.

The Role of Technology in Modern Calibration Processes

Modern era has revolutionized how we mindset calibration. Automated systems can now participate in calibrations with high precision and much less human intervention.

Quality Assurance in Calibration

Ensuring high quality coverage includes setting up protocols that agree to ISO necessities and other regulatory requisites.

Common Challenges within the Calibration Process

Inconsistent Measurement Conditions

Variations in temperature or humidity can affect dimension accuracy all through calibration tactics.

Instrument Drift

Over time, devices may additionally glide from their fashioned settings because of wear and tear or environmental motives.

Lack of Documentation

Failing to report techniques and consequences can cause fast calibration company near me non-compliance with regulatory necessities.

Best Practices for Effective Calibration

Regular Training for Personnel

Ensure that body of workers in contact in calibration suffer established instructions periods to keep updated on prime practices and technology.

Use of Digital Tools

Embrace digital options corresponding to instrument applications designed especially for managing calibration schedules and records.

FAQs About the Calibration Process

Q1: How occasionally should still I calibrate my instruments?

A1: The frequency depends on countless points along with utilization intensity, organization recommendations, and industry rules; mostly each six months is straight forward.

Q2: Can I operate calibration alone?

A2: While ordinary checks is perhaps done in-condominium by skilled staff, pro calibration services are beneficial for high-precision gadget.

Q3: What's the price in contact in specialist calibration?

A3: Costs vary largely headquartered on tool kind however be expecting at any place from $100 to quite a few thousand money relying on complexity.

Q4: What occurs if I don’t calibrate my tools?

A4: Failure to calibrate might induce inaccurate measurements most excellent to high-quality troubles or protection hazards.

Q5: Is there an accreditation frame for calibration providers?

A5: Yes! Many nations have accrediting our bodies like ISO/IEC 17025 which ensures labs meet bound standards referring to their trying out abilities.

Q6: What documentation do I desire submit-calibration?

A6: You need to deal with archives including previous calibrations, adjustment info, same old deviations followed right through checking out periods, and so on., as they might be required by means of regulatory companies or auditors.

Conclusion

Understanding the calibration strategy is integral now not purely for sustaining compliance but additionally for guaranteeing caliber throughout a large number of industries. By following this step-through-step support—spanning from opting for what wants calibrating all the manner with the aid of documenting your findings—you are going to be neatly-provided to navigate this valuable point of operational excellence. Remember that regular tracking and updating practices will yield long-term benefits in accuracy and reliability. So equipment up! Your travel towards studying the paintings of calibration starts offevolved at the moment!

This dependent means grants readability although ensuring a radical awareness—empowering you with equally experience and confidence as you have interaction with this indispensable practice generally referenced the following across "Understanding the Calibration Process: A Step-by-Step Guide."